Corey Bailey

Audio Engineering

GLOSSARIES

ANALOG TAPE

A-Wind

Meaning; ‘Oxide in.’ An audio tape that has been wound in an

A-Wind, will have the tape oxide on the inside layers and the tape backing

towards the outside. This is how audio tape has been wound and delivered for

about 70 years.

Acetate tape

Acetate Tape refers to the material used as the base for

tapes manufactured from the early 50’s through the

1970’s. During the 1970’s, Polyester became the

preferred base material for analog tape. It’s worth noting

that each material has exhibited problems over time.

The acetate base becomes brittle over time. When

conditions are very dry, the tape can deform, causing a

condition known as ‘cupping’ and the tape will take the

shape of a metal Venetian blind. Too much moisture

during storage can cause a condition known as

‘vinegar syndrome’ in which the acetate base releases

acetic acid and the tape will have a vinegar odor.

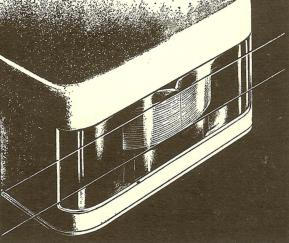

FIG. 1 to the right, is an illustration of a typical tape

recorder head. The vertical line in the center

represents the head gap.

Azimuth

In the world of magnetic tape recorders, azimuth refers to the alignment of the

head gap relative to the direction of travel of the tape. This involves mainly the

record and playback heads however, on some tape machines, the erase head is

also adjustable.

The head gap represents the centerline of each head and should be precisely

90 degrees to the tape.

Any variation from 90 degrees will result in a loss of high frequency information.

Azimuth is one of the adjustable parameters of each head and there are specific

methods to check and adjust for the proper alignment.

B-Wind

Meaning; ‘Oxide out.’ During the dawn of analog tape recording, some tape

recorders used audio tape with the oxide facing out. In the early days of tape

recording, one could buy audio tape that was wound that way. Nowadays, a

B-Wind is sometimes used to reduce ‘Cupping’ on Acetate base tapes.

Back Coating

Many brands of professional polyester audio tape had a coating on the backside

of the tape (opposite the oxide). Many brands of audio tape had a back coating

that was electrically conductive. The back coating performs some important

functions;

1) The foremost purpose is to help prevent static buildup, which can cause arcing

and subsequent audible snaps in the recording.

2) While helping to eliminate static, the same back coating allows for more even

packing (winding) of the tape on the reel.

3) The back coating also serves as an insulating layer that helped prevent print

through, a condition in which the recorded magnetic field migrates from one layer

of the tape to another.

Bias

In a tape recorder, bias is a high frequency Alternating Current (AC) signal that is

applied to the erase and record heads during recording. The reason for the bias

signal is to magnetize the ferrous iron particles in the oxide in a manner which

provides the best linearity for recording. The frequency of the bias signal is

supposed to be at least 10 times the highest audio frequency capable of being

recorded by a given recorder (but rarely is). A typical bias frequency for consumer

recorders is anywhere between 40 kilohertz (forty thousand cycles per second)

and 100 kilohertz (kHz). Professional equipment can have a bias frequency

approaching 250 kHz. The fact is, anything that can be magnetized, does not

magnetize in a linear fashion. Early attempts to record without a bias signal, on

an oxide containing iron particles, resulted in poor frequency response. Applying

a DC (Direct Current) bias proved to be of little benefit.

The first patent for AC bias for use in electronics was filed by W. L. Carlson and

Glenn L. Carpenter in 1921. However, it was Walter Weber who employed the

technique of applying AC Bias to magnetic tape recording.

Binder Hydrolysis

This is a condition where the chemical binder in the oxide has absorbed moisture

over time to a point that causes a chemical change in the composition of the

oxide itself. This often results in Sticky Shed syndrome. Another variation in the

decomposition of the oxide results in a milky-colored stain on the surface of the

oxide that dramatically increases the friction during playback,

often causing the tape or magnetic film to come to a stop.

Coercivity

For magnetic tape, Coercivity refers to the strength of a given magnetic field

required to reduce the recorded magnetic field (signal) on the tape to zero after

the oxide has been driven into saturation. Tapes using an oxide with greater

coercivity, generally require a stronger Bias signal.

Capstan

On a tape recorder, the Capstan is the rotating vertical shaft that pulls the tape

past the heads. The tape is usually squeezed between the Capstan and a

rotating wheel known as the Pinch Roller.

Degausser

A device that emits a strong enough Alternating Current magnetic field to

completely erase magnetic media or magnetized metal parts and tools.

Demagnetization

Simply stated: “The process of removing magnetism from any material that can

be magnetized.” In tape recording, tapes are demagnetized by being exposed to

an AC field strong enough to overcome the coercivity of the tape. On audio tape

decks, this process is accomplished by the erase head during recording.

Also on audio tape decks, the metal parts that come in constant contact with the

tape (particularly, the tape heads themselves) can become magnetized over time

and have to be demagnetized using a portable degausser.

The process of demagnetizing the heads and various parts of a tape deck has its

own learning curve. If done improperly, one can actually magnetize the intended

parts and cause harm to tapes that are subsequently played on that machine.

Dropout

A dropout is a brief loss or sudden decrease of signal level (volume), most often

caused by a defect in the tape oxide. Dropouts can also be caused by damage to

the tape itself, a temporary clogging of the record head during recording, or

likewise, a clogging of the play head during playback. Tape oxide defects can

cause frequency-selective dropouts, such as a brief loss of high frequency

information. Tape speed can be a factor in the effect of tape-defect related

dropouts as the condition is less noticeable at higher tape speeds.

Dynamic Range

In the world of audio, Dynamic Range is defined simply as the range of volume

from the loudest to the softest of sounds. Dynamic Range is expressed in

decibels (dB) which is a logarithmic scale.

We Recording Engineers, often refer to Dynamic Range in terms of the difference

between the loudest undistorted signal that be recorded down to the noise level

(floor) of a given medium. Analog tape is capable of a dynamic range of roughly

70dB. A Compact Disk (Audio CD) has a theoretical dynamic range of 96dB. The

average human can hear a dynamic range of approximately 140dB.

Erase Head

The erase head on an analog tape recorder is self explanatory, it erases tape!

It does so by being energized by the bias oscillator with enough voltage and

current to saturate the tape with the bias frequency.

The erase head is usually only energized during recording. The erase head

is also the first to come on contact with the tape during recording. If you view the

heads of a reel-to-reel tape deck straight on, the erase head will be on the left.

Flanging

Flanging is an effect that was originally created by using two analog tape decks

playing the same material in sync with each other. The operator would put gentle

pressure on the supply reel of one of the tape decks, causing the speed to

change slightly. The resulting speed change caused random parts of the signal to

react with each other and the result was recorded. Because this process is phase

related, it was often known as ‘Rubbing.’ It didn’t take long for hardware to appear

on the scene, eliminating one of the tape decks. The signal was played through

the hardware and all the operator had to do was turn a knob to achieve the

desired effect. Now, the effect can be created digitally with software.

Flutter

Tape recorders are designed to pass the tape across the heads at a very

constant speed. Any changes in the tape speed of a pre-recorded signal are

perceived as changes in pitch. If these speed changes occur very rapidly, the

effect is a ‘fluttering’ sound. Hence, the term. Flutter can be caused by something

as simple as a piece of tape that becomes inadvertently wrapped around the

capstan or a very worn pinch roller.

A type of tape degradation known as Sticky Shed Syndrome can cause flutter as

the tape itself tends to chatter across the heads.

Guides

Tape guides are generally stationary posts that are placed very near the heads to

keep the tape in proper vertical alignment. Worn guides can not only loose their

ability to keep the tape properly aligned but can actually damage tape as it is

passed across them.

Heads out

Holding a reel of audio tape in front of you, the tape will un-spool from the left.

In order to indicate the state of the tape, the loose end is usually folded and

fastened to the reel with adhesive paper tape in such a manner that the folded

and taped end will face the operator when the reel is placed on the machine

(or a table, for that matter). This makes it easy to identify which way to mount a

given reel of tape onto the tape deck.

IPS (Inches Per Second)

The linear speed of the audio tape as it is played on the tape deck. Tape speeds

vary from as slow as 15/16 IPS to as much as 30 IPS for analog tape machines.

Reel-to-reel digital audio tape machines will typically operate at a greater speed.

Generally speaking, for analog tape, the faster the tape speed the better the

sound quality. Tape speeds of 3-3/4 & 7.5 IPS were common for consumer tape

recorders and professional machines typically operated at 15 & 30 IPS.

Leader

Audio tape leader is a paper or plastic product cut the same width as the tape.

Leader is used to separate specific segments of audio tape, such as each song

on music masters. Leader is typically added to the beginning of a reel and often

to the end of a reel of tape. Leader that has been applied to both ends of an

audio tape will protect the first couple of wraps of the tape at the head and protect

the tape from the threading slots on the center of the reel at the other end. Some

manufactured tape comes with leader already attached to the tape. Some plastic

leader is printed with markers for every second of time and is called: ‘Timing

Leader’

Library wind

This is a process whereby the tape is wound from one reel to the other at

reduced tension and at a speed that is much slower than full rewind speed.

Typically, around 45 IPS. This results in a very even wind on the take-up reel, and

a tails-out configuration which, is desirable for long term storage.

Lifters

The tape lifters are vertical posts that usually reside near the heads of a tape

recorder and are energized during fast-forward or rewind. During this process,

the lifters move the tape away from the heads to prevent wear during the high

speed shuttling of the tape. Know that the tape lifters are usually stationary while

the precious oxide is whizzing past and in direct contact with them.

Noise Reduction

Numerous articles and books have been written on this subject, and it is difficult

to summarize Noise Reduction in a few sentences. When it comes to analog tape

recording, there are two basic approaches:

Single-Ended and Dual-Ended.

Single-Ended systems generally deal with tape hiss and other anomalies after

the fact or after the recording is made. Today’s digital editing software is often

designed to be able to improve upon recorded anomalies after the fact and is a

good example of a ‘single-ended’ approach. A number of hardware devices were

made during the analog era for single-ended noise reduction by companies like

Burwen, DBX, Phase Linear, SAE, etc. and can still be found on the vintage

hardware market. These hardware devices work in ‘real time,’ meaning that the

recorded audio has to be played through them for processing.

Dual-Ended noise reduction involves processing the audio signal before and

after recording. Ray Dolby first applied this process in 1966 with the introduction

of Dolby A type noise reduction intended for use with professional audio tape

recording. Dolby Laboratories subsequently introduced noise reduction

processes for the consumer market and became a household word.

Besides Dolby Laboratories, DBX and Telefunken produced very effective dual-

ended systems that were used in both professional and consumer recording.

Oxide

This is the composition that has been applied to the side of magnetic tape that

contains the magnetic recording. Oxide consists of a slurry containing the metal

particles, a binder solution which, helps adhere the oxide to the backing,

lubricants to make the dried solution both flexible and less physically noisy when

passing across the heads, and several other chemical compounds.

The actual chemical composition of oxide remains a closely guarded secret by

the various manufactures of magnetic tape.

Pinch Roller

The Pinch Roller (sometimes referred to as a ‘puck’) on a tape deck is that round

wheel that presses the tape against the capstan to move the tape across the

heads. Pinch rollers are free-wheeling and are usually made of rubber or a semi-

soft composite material.

Playback Head

If you were able to view the construction of a play head, it would look somewhat

like a horse shoe with several turns of fine wire wrapped around it.

The tape is pulled across the gap of the horse shoe shape.

The actual gap is tiny (microns, in fact) in order to concentrate the magnetism

that has been imparted onto the tape by the record head.

See FIG. 1 for an illustration of a tape recorder head. If you view the heads of a

reel-to-reel tape deck straight on, the play head will be on the right.

Play Wind

This is how the tape winds up on the take-up reel after being played from left to

right. A ‘Play Wind’ is considered to be desirable for long term storage.

The reason is that if print through occurs, the print-through information will be

after the recorded audio and be masked or sound like echo.

If the tape is stored heads-out, the print-through information can precede the

recorded audio on the tape and is known as ‘pre-echo.’

Polyester tape

This refers to the type of base material used for audio and video tape.

Polyester, sometimes referred to as PET, is a substance known scientifically as

Polyethylene Terephthalate. (I can’t pronounce it well either!)

Polyester back tapes are known to have problems when the oxide absorbs

moisture over time. This usually causes a condition called Sticky Shed Syndrome

(SSS). Layer to layer adhesion problems can sometimes happen.

When this happens, the unfortunate result is that the oxide can separate from the

base and stick to the preceding layer of tape or literally fall off in some instances.

That condition is generally unrepairable.

Print Through

When audio tapes are tightly wound on a reel and/or stored for extended periods

of time, the adjacent layers can sometimes influence each other. That is, one

layer can partially magnetize an adjacent layer. This condition can be more

predominant if the recorded levels are extremely loud or ‘hot,’ non back coated

audio tape or with thinner varieties of audio tape. The use of conductive back

coatings on many brands of audio tape helped alleviate this condition. If the tape

is wound heads-out, the partial magnetization will sound like pre-echo. This is

one of the reasons for storing audio tapes tails-out. If print through occurs in a

tails-out wind condition, it is either masked or sounds more like natural echo. It

has been recommended by some that stored audio tapes be periodically rewound

and stored again, using a play wind or preferably, a library wind. Periodically

rewinding audio tape is a very labor intensive process which,

in practice, is rarely done.

Record Head

The main difference between a record head and a playback head is the size of

the gap between the poles of the head itself. We’re talking microns here.

However, the gap on a record head is typically wider than that of a playback

head. See FIG. 1 for an illustration of a tape recorder head. If you view the heads

of a reel-to-reel tape deck straight on, the record head will be in the center of a

three head tape deck.

Round Robin

This is an effect that causes a repeating of the signal. It is actually a type of

feedback that is created by playing the signal into a mixing console and assigning

the signal back unto itself. Nowadays, the effect can be created digitally with

software.

Saturation

This is the state reached with magnetic tape when the oxide has been

magnetized to the point where it cannot be magnetized any further. Exceeding

this threshold with an alternating current magnetic field (via the record head) will

cause the magnetic particles in the oxide to become disoriented, and audible

distortion occurs.

Signal-to-Noise Ratio

In engineering or scientific terms; Signal-to-noise ratio refers to the strength of a

given signal in relation to the background noise associated with that signal.

Signal-to-Noise Ratio can be applied to everything from astronomy to video to

analog & digital audio recording. It is often abbreviated as SNR or S/N.

Recording engineers will sometimes increase the signal-to-noise ratio of analog

tape by increasing the reference level of the recording. The overall increase is

small but often noticeable, depending on the material.

Sticky Shed Syndrome

Abbreviated SSS, this condition is particularly damaging to the tape being played.

It’s a condition whereby the binders and lubricants in the oxide have absorbed

enough moisture over time to cause the oxide to become soft. When played on a

tape recorder, the characteristic symptom is often a squealing or squeaking

sound which modulates the audio being played. The tape will often shed oxide on

all of the stationary parts of the tape deck. The accepted but temporary, fix is to

carefully bake the tape under controlled conditions.

The Digital Audio Tape formats have recently shown signs of SSS so, if you own

any of these, now is the time to inspect them. Unfortunately, these formats will

typically not show a problem until they are played and, then it can be too late for

your prized digital audio recorder. (Particularly the rotary head formats)

Sound-on-Sound

An effect (sometimes a mistake) whereby a signal is recorded onto an existing

recording. When played back, both signals can be heard but not separated.

This process is made possible by disabling the erase head when applying the

second signal to an existing recording.

Tails-out

Holding a reel of audio tape in front of you, the tape will un-spool from the right.

In order to indicate the state of the tape, the loose end is usually folded and

fastened to the reel with adhesive tape in such a manner that the folded and

taped end will face the operator when the reel is placed on the machine or any

flat surface. This makes it easy to identify which way to mount a given reel of tape

onto the tape deck.

Tape Baking

The process of baking analog tape involves raising the ambient temperature of

the tape to 120 - 130 degrees Fahrenheit (48.8 – 54.4 degrees Celsius) in a very

low humidity environment for specific amounts of time based on the width of the

tape, the thickness of the tape and the size of the reel. The process was first

proposed (even patented) by AMPEX Corporation in the early 1990's.

This procedure can only be applied to Polyester base tape.

Acetate base tape can be damaged by this process.

VSO

VSO stands for Variable Speed Oscillator. A VSO is used on a an analog tape

recorder that has a DC capstan motor to vary the speed of the tape. Some

recorders had a speed control built in and others required an external device.

Tape recorders that use an AC sync motor as the capstan motor, are generally

not speed controlled.

Wow

The sudden change of pitch of a recorded signal caused by physically altering the

tape speed for a very short duration of time. The reasons for the occurrence can

be everything from mechanical failure of the tape recorder, to tape damage. Wow

can also be created purposely by applying enough pressure to the supply reel

during playback to momentarily alter the tape speed.

Zenith

On an audio tape recorder, Zenith refers to the relationship of the vertical

alignment of the face of each head and the tape guides to the deck plate or

mainframe in order to provide even contact over the entire surface of the tape.

Zenith, like Azimuth, is usually an adjustable parameter of each tape head.

References

Howard M. Tremane, “Audio Cyclopeia” Second Edition, Howard W. Sams, 1973

Rudolph F. Graf, “Dictionary of Electronics” Howard W. Sams, 1974

Glenn D. White, “The Audio Dictionary” University of Washington Press, 1987

Dr. John W. C. Van Bogart, “Magnetic Tape Storage and Handling” National

Media Lab, 1995

Wikipedia, http://www.wikipedia.org/

Return to TOP of page

© Corey Bailey Audio Engineering

FIG. 1

This image is from the

inside of a Scotch 111

tape box. (Acetate base)